Rugged Computing Technology

Made in Germany

In-house development

noax has been developing and producing industrial computers at its corporate headquarters in Ebersberg, Germany, for over 25 years. On the one hand, the empirical values from a quarter of a century of IPC development from motherboard generation to generation flow into the development; on the other hand, we can react agilely and flexibly to individual requirements thanks to the proximity to our customers and direct communication.

Unconditional quality as a corporate principle

The origin of the noax company arose from the desire to be able to offer customers complete CNC software and hardware solutions. Initially, an attempt was made to buy in parts from external suppliers. However, after external industrial hardware providers were unable to deliver robust or long-lasting solutions, the decision was made to develop the first industrial computer in-house in 1990. Due to the close cooperation with the end customer, the industry-specific customer requirements could be taken into account during development.

The quality requirements of the industrial requirements explain why standard solutions are not used during development, but rather the devices are designed in every aspect according to the requirements of the industry:

-

Robustness against external influences such as water, dust, dirt, shock and vibrations up to IP69K.

-

Hygienic design with the highest IP protection in the food & pharmaceutical sector

-

Reliability and guarantee of connectivity with a slim design in the area of logistics & transport

-

Guarantee of long running times over years and decades in 24/7 continuous operation in all areas.

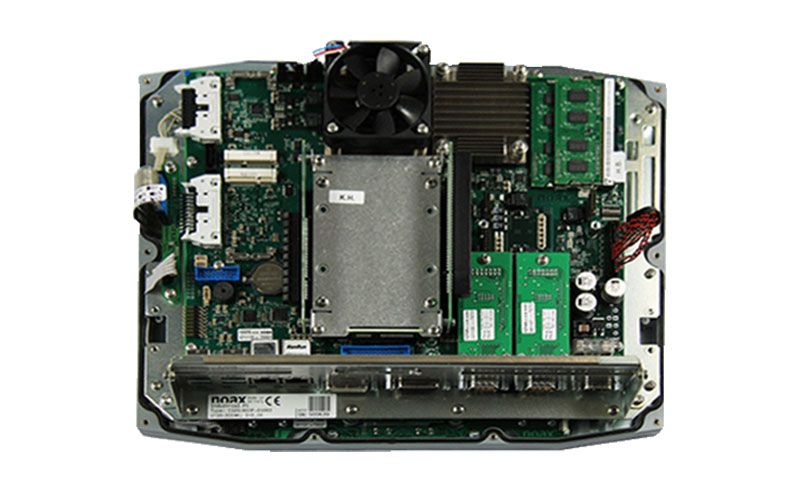

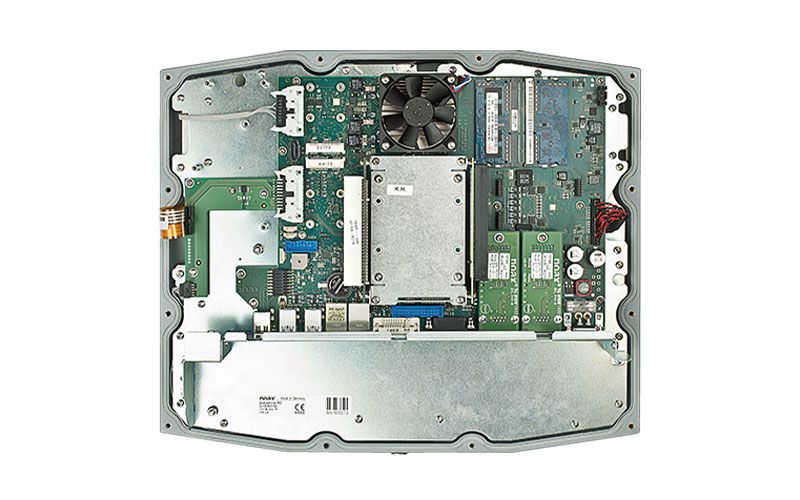

100% industrial components

In the development of the noax mainboards, only high-quality industrial components are used, which undergo numerous internal stress tests (including a 48h burn-in test). The composition of the components not only determines the performance of the device, but also plays a decisive role in terms of thermal management. Last but not least, this ensures the long availability of the devices and their spare parts.

Long availability & uniform images

In addition to the qualitative aspects of in-house development and production, the long availability of hardware plays a decisive role in procurement. We therefore pay attention to the long-term availability of the individual components when developing the devices. This guarantees you long-term industrial PC spare parts availability and an availability guarantee. The use of standardized PC technology ensures that it can be retrofitted and upgraded at any time, is compatible with all common hardware and software systems, and is easy to install in the existing production and IT landscape. For you this means that also with the new installation.

Expandability

Industry 4.0 is fast moving. New developments also result in new requirements for IT hardware. Be it the need for a new interface or the expansion of storage capacity. noax industrial computers can be upgraded and retrofitted at any time. Even when developing our mainboards, we ensure 100% compatibility, for example through:

- Consistent use of industrial grade Intel chipsets

- Use of standardized PC technology

- Expansion through PCI / PCI-Express cards

The long availability of spare parts in connection with the modular expandability of noax industrial computers ensures peace of mind for years to decades. The devices do not have to be dismantled and sent in, which is time-consuming and costly, but can be extended without loss of guarantee and without loss of IP protection.

Get your free Test device

Test us out at your facility to see how tough a noax computer actually is!

INDUSTRIES

CONTACT

-

P (704) 992-1606

-

F (704) 992-1712

© noax Technologies. All rights reserved.